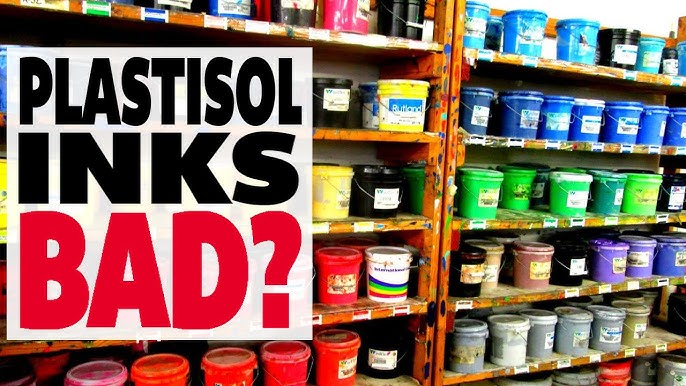

What is Skip Marsh Plastisol Ink?

Skip Marsh Plastisol Ink is a popular choice for screen printing due to its exceptional quality and ease of use. It is a PVC-based ink that remains flexible, durable, and vibrant after curing. Skip Marsh Plastisol Ink is designed to be used on various fabrics, including cotton, polyester, and blends. Unlike water-based inks, plastisol inks do not dry out quickly, making them ideal for large production runs.

The key characteristic of plastisol ink is that it sits on top of the fabric, rather than absorbing into it, resulting in a more vibrant and durable print. This ink also offers high opacity, which is essential for printing on dark fabrics. Whether you’re a beginner or an experienced printer, Skip Marsh Plastisol Ink delivers consistent results, making it a go-to choice for screen printing projects.

Key Features of Skip Marsh Plastisol Ink

Skip Marsh Plastisol Ink stands out in the world of screen printing for its robust features that ensure high-quality results. Here are the key attributes that make it a preferred choice for many screen printers:

- Durability: This ink is known for its long-lasting prints that can withstand wear and tear, making it ideal for garments that will undergo frequent washing or heavy use.

- Opacity: Skip Marsh Plastisol Ink provides excellent opacity, allowing vibrant colors to show up clearly on both light and dark fabrics.

- Ease of Use: Its user-friendly application process makes it suitable for both novice and experienced printers.

- Versatility: This ink works well on a wide range of fabrics, from cotton and polyester to blends.

- Vibrancy: It maintains rich, vibrant colors that do not fade easily, ensuring that prints look fresh and bold for longer.

The Benefits of Skip Marsh Plastisol Ink for Screen Printing

Using Skip Marsh Plastisol Ink for your screen printing projects comes with a host of benefits. Below, we explore the major advantages that make this ink a preferred choice for many printers.

High Durability and Long-Lasting Prints

One of the standout benefits of Skip Marsh Plastisol Ink is its durability. Once cured, the ink forms a thick, flexible layer that adheres firmly to the fabric. This means prints made with this ink resist cracking, fading, and peeling, even after multiple washes. Whether you’re printing T-shirts, hoodies, or other garments, your designs will retain their quality over time.

Ease of Application

Skip Marsh Plastisol Ink is incredibly easy to work with, making it a great choice for both beginner and expert printers. The ink’s consistency allows for smooth application, reducing the chances of clogging or uneven printing. Whether you’re using manual or automatic screen printing presses, you’ll find that Skip Marsh Plastisol Ink offers consistent results.

Opacity on Dark Fabrics

One of the challenges when screen printing on dark fabrics is achieving full opacity. Plastisol inks, including Skip Marsh, excel in this area. Their high opacity ensures that the design shows up vibrantly on dark or black fabrics without the need for multiple layers of ink. This makes it especially useful for printing T-shirts and other apparel in darker colors.

Vibrant Colors and Consistency

Skip Marsh Plastisol Ink is known for producing vibrant, bold colors that remain consistent throughout large production runs. The ink offers a wide color range, ensuring that every print job, whether large or small, can achieve the desired color effect without worrying about color discrepancies or fading over time.

Environmental Benefits

While traditionally, plastisol inks have been criticized for their environmental impact, Skip Marsh has made strides toward creating more eco-friendly formulations. The ink is now available with reduced levels of harmful chemicals, making it safer for both printers and the environment. Additionally, unlike water-based inks, plastisol does not dry out easily, which helps reduce waste in screen printing operations.

How to Use Skip Marsh Plastisol Ink for Screen Printing

To achieve the best results with Skip Marsh Plastisol Ink, it’s important to follow the proper procedures. Here’s a step-by-step guide to help you use this ink effectively:

Preparing the Screen

- Clean the Screen: Ensure the screen is free of any debris, old ink, or oil. Use a screen cleaner to remove any contaminants.

- Apply the Emulsion: Coat the screen with emulsion and let it dry completely. Make sure the screen is free from streaks or bubbles.

- Exposure: Expose the screen to light using a screen exposure unit to create your stencil.

Mixing the Ink

Skip Marsh Plastisol Ink is typically ready to use, but you may need to mix it to achieve the right consistency. If you need to thin the ink, use a plastisol reducer. Avoid adding too much thinner, as it can compromise the opacity and color vibrancy.

Printing the Design

- Set Up the Press: Load your screen onto the press and align the fabric beneath it.

- Apply Ink: Pour the ink onto the screen and use a squeegee to push it through the mesh. Ensure even coverage for a consistent print.

- Lift the Screen: Once the ink has been transferred, lift the screen to reveal the printed design.

Curing the Print

Curing is essential to ensure that the print is durable and long-lasting. Use a flash dryer or conveyor dryer to heat the printed garment to the required temperature. The typical curing temperature for plastisol ink is around 320°F (160°C). Make sure the ink is fully cured to avoid smudging or washing out.

Common Issues and Troubleshooting Tips

Though Skip Marsh Plastisol Ink is easy to work with, there can be challenges during the printing process. Below are common issues and how to address them:

Ink Not Curing Properly

If your prints are not curing properly, they may not adhere to the fabric well, leading to smudging or fading. Ensure that the curing temperature is high enough and that the ink is fully heated. If the print feels tacky after curing, it may not have been exposed to enough heat.

Inconsistent Prints

Inconsistent prints can occur if the ink is not mixed well or if the screen mesh is clogged. Always ensure that your ink is evenly mixed and your screen is clean before printing.

Smudging or Ghosting

Smudging or ghosting often happens when the print hasn’t been fully cured or when there’s excess ink on the screen. Reduce the amount of ink on the screen and ensure that the prints are properly cured.

Ink Drying in the Screen

If the ink starts drying on the screen, it can clog the mesh, leading to uneven prints. To avoid this, keep the screen moving, and avoid prolonged exposure to heat or air when the ink is still wet.

When to Choose Skip Marsh Plastisol Ink

Skip Marsh Plastisol Ink is ideal for various screen printing applications, but it’s especially useful when you need vibrant, durable prints. It’s perfect for high-volume runs where consistent results are crucial. If you’re working with dark fabrics or need to print intricate designs with sharp details, Skip Marsh Plastisol Ink is a reliable choice.

Conclusion

Skip Marsh Plastisol Ink is a high-quality, versatile solution for screen printing that offers durability, opacity, and vibrant colors. Whether you’re printing on light or dark fabrics, Skip Marsh provides consistent results, making it a top choice for screen printers worldwide. By following the proper techniques for mixing, applying, and curing the ink, you can achieve professional results for any screen printing project.

FAQs

1. What is the difference between Skip Marsh Plastisol Ink and other plastisol inks?

Skip Marsh Plastisol Ink offers superior opacity, ease of use, and durability compared to other plastisol inks. It also has an improved environmental formula, making it safer for use.

2. Can Skip Marsh Plastisol Ink be used for printing on all fabrics?

Yes, Skip Marsh Plastisol Ink can be used on a variety of fabrics, including cotton, polyester, and blends. It is especially effective on dark fabrics due to its high opacity.

3. How long does it take to cure Skip Marsh Plastisol Ink?

The ink typically cures at around 320°F (160°C) for 1-3 minutes, depending on the thickness of the ink layer.

4. Is Skip Marsh Plastisol Ink environmentally friendly?

Yes, Skip Marsh Plastisol Ink has made significant strides in reducing harmful chemicals, making it a safer and more eco-friendly option compared to traditional plastisol inks.

5. Can I use Skip Marsh Plastisol Ink without a dryer?

It’s highly recommended to use a conveyor dryer or flash dryer to ensure proper curing of the ink. Air drying is not sufficient for long-lasting results.

2 Comments

This is such a fantastic post! Your work on this topic is extremely commendable and your style is highly captivating. Keep up the amazing work!

Your website provides a distinctive perspective on related topics. I like the approach you present information.